Folks, I know this might be a stretch but here goes...

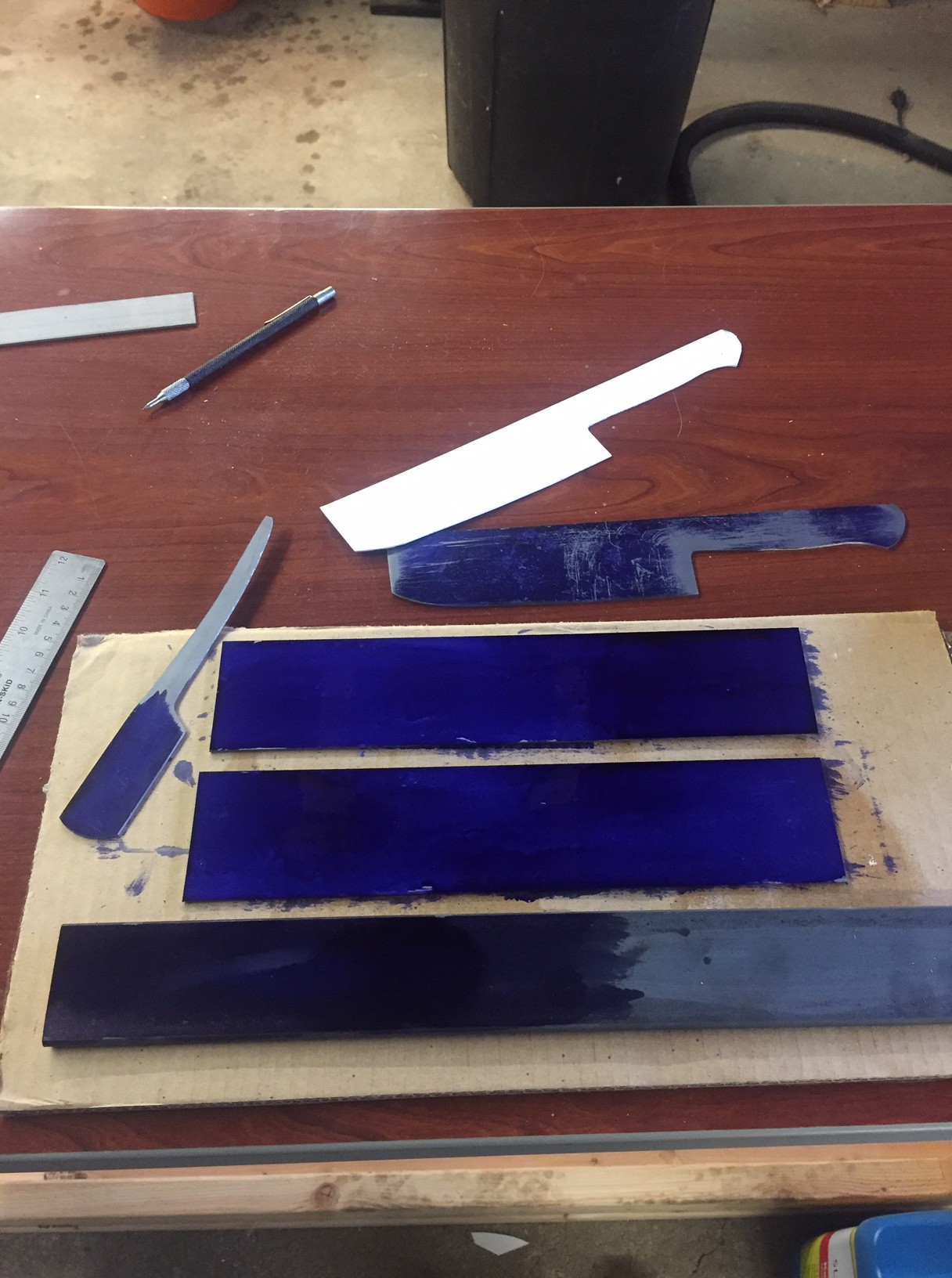

Yes, I know the word kamisori isn't a verb, but I'm inspired. I'd love to try my hand at making a kamisori, but really don't want to spend the money to buy one just to get some measurements. I googled, but couldn't find any specific diagrams that list dimensions. Does anyone have one that would be kind enough to measure the length of the shaving edge, the thickness of the spine as well as the overall length?

Thanks in advance,

Pete VK

Yes, I know the word kamisori isn't a verb, but I'm inspired. I'd love to try my hand at making a kamisori, but really don't want to spend the money to buy one just to get some measurements. I googled, but couldn't find any specific diagrams that list dimensions. Does anyone have one that would be kind enough to measure the length of the shaving edge, the thickness of the spine as well as the overall length?

Thanks in advance,

Pete VK