Hi,

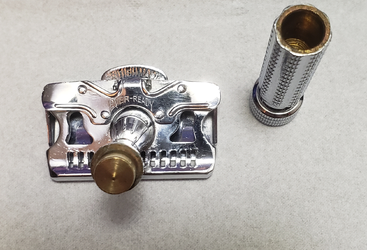

I've recently been getting into vintage GEM-style razors, and my latest acquisition has a problem with the handle coming loose. I was hoping someone has some advice on how to secure it properly- simply push-fitting hasn't worked, and it's rather disconcerting to have it come loose during a shave! It's a shame, as it's my favourite razor of its kind so far.

I've got some epoxy resin, but I'd rather get some advice before committing to something like that.

I've recently been getting into vintage GEM-style razors, and my latest acquisition has a problem with the handle coming loose. I was hoping someone has some advice on how to secure it properly- simply push-fitting hasn't worked, and it's rather disconcerting to have it come loose during a shave! It's a shame, as it's my favourite razor of its kind so far.

I've got some epoxy resin, but I'd rather get some advice before committing to something like that.

Excellent shave with my Ever-ready Streamline 2nd Gen with a coated Gem blade.(does not get any better for me today for closeness and no issues!)

Excellent shave with my Ever-ready Streamline 2nd Gen with a coated Gem blade.(does not get any better for me today for closeness and no issues!)