How is it possible that an edge gets sharper after using it?

Last night I spent some time reworking the edge on a new rescue razor. I got the razor shaving well but there was still a small section of the toe missing an edge. I also noticed a few little chips that I hadn’t cleaned up 100% in my initial honing effort.

Progression was

Shapton HR 500 -> 1k -> 3k -> 10k -> Thuri (slurry to water dilution)

I went through the motions observing and testing as I went. Everything looked sweet. Chips were cleaned up, no reflections looking straight down on the edge at 10x, honing scratches cleaned up nicely and evenly. Tomato test and finger nail tests were all good. But then the moment of truth. Stropping and HHT. Meh HHT… Meh tree topping... Kind of worked but not really there if you know what I mean.

Determined to get it right this time, I ran the progression again. And again… With the same result. The HHT was kind of weak. Tree topping would pop the odd hair but that was it. Everything looked good but the tests were off.

Eventually, after staying up way too late, I gave up and resolved to test the edge in the morning with a good blade on standby. The first few shave stroke felt ok. No tugging. Is this thing even cutting? Yes it is. Nice and smooth with lots of stubble on in the lather. So I continued using it with no need for the standby razor. Rinsed off and had a feel round my face. Nice shave.

Then out of interest I tested the razor again (without stropping). Now the razor was tree topping brilliantly. After stropping it was singing.

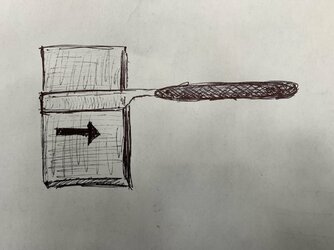

What’s going on here? The only thing I can think of is that shaving removed some sort of burr from the edge. It looked a lot like the @cotedupy video where he tests a knife before and after sawing through a cardboard roll. The ‘dull’ knife suddenly becomes sharp after it is deburred.

Am I missing a deburring step in my honing?

A few other observations.

1. After a failed stone progression, I will often fall back on lapping film and balsa. The Method edge always passes the HHT at the end. One difference is that I will incorporate lateral “pull strokes” in line with The Method doctrine.

2. I often notice improvement in razor edges after a few ‘shave-touchup’ cycles following a big honing session.

Any idea what’s going on here?

Last night I spent some time reworking the edge on a new rescue razor. I got the razor shaving well but there was still a small section of the toe missing an edge. I also noticed a few little chips that I hadn’t cleaned up 100% in my initial honing effort.

Progression was

Shapton HR 500 -> 1k -> 3k -> 10k -> Thuri (slurry to water dilution)

I went through the motions observing and testing as I went. Everything looked sweet. Chips were cleaned up, no reflections looking straight down on the edge at 10x, honing scratches cleaned up nicely and evenly. Tomato test and finger nail tests were all good. But then the moment of truth. Stropping and HHT. Meh HHT… Meh tree topping... Kind of worked but not really there if you know what I mean.

Determined to get it right this time, I ran the progression again. And again… With the same result. The HHT was kind of weak. Tree topping would pop the odd hair but that was it. Everything looked good but the tests were off.

Eventually, after staying up way too late, I gave up and resolved to test the edge in the morning with a good blade on standby. The first few shave stroke felt ok. No tugging. Is this thing even cutting? Yes it is. Nice and smooth with lots of stubble on in the lather. So I continued using it with no need for the standby razor. Rinsed off and had a feel round my face. Nice shave.

Then out of interest I tested the razor again (without stropping). Now the razor was tree topping brilliantly. After stropping it was singing.

What’s going on here? The only thing I can think of is that shaving removed some sort of burr from the edge. It looked a lot like the @cotedupy video where he tests a knife before and after sawing through a cardboard roll. The ‘dull’ knife suddenly becomes sharp after it is deburred.

Am I missing a deburring step in my honing?

A few other observations.

1. After a failed stone progression, I will often fall back on lapping film and balsa. The Method edge always passes the HHT at the end. One difference is that I will incorporate lateral “pull strokes” in line with The Method doctrine.

2. I often notice improvement in razor edges after a few ‘shave-touchup’ cycles following a big honing session.

Any idea what’s going on here?

Last edited: