I've gathered some info on these stones, having interest in them since I live in Indiana. Figured I'd post it and start a dedicated thread for these guys. The following text info was compiled and typed up from a few different old Indiana geological reports from the mid to late 1800's.

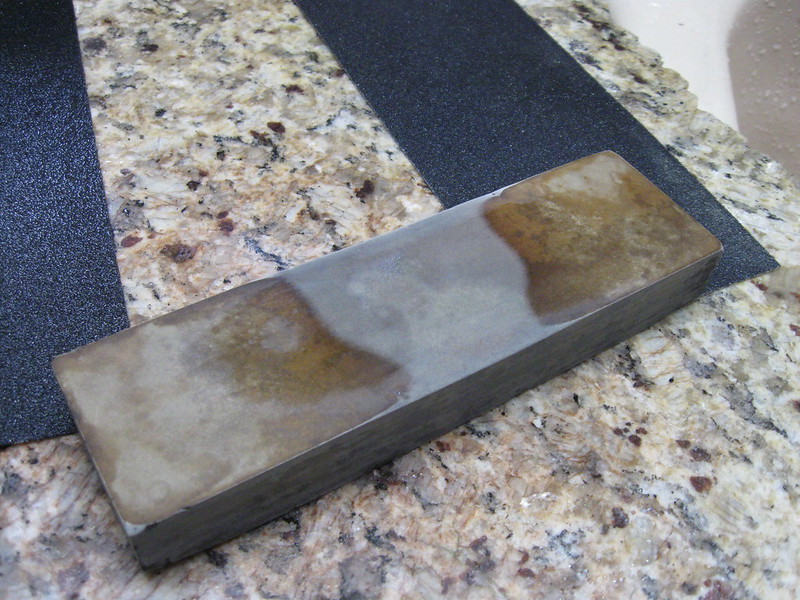

Quick summary, I find it most interesting that the stones can range from nearly pure white, to bluish gray, to orange with or without whiter swirls, to red. They can have black or brown spots, or not. They can have manganese swirls, or not. They are a type of quite fine-grained sandstone with nearly uniform particle size of on average (in the vast majority of samples tested) about 20 microns - though they can be as small as 10 microns or as large as 32 microns.

DESCRIPTION: - Hindostan stone from different quarries and from different strata in he same quarry presents considerable variation in physical characters. The best grade of stone, which is called "Washita Finish" stone, due to its resemblance to Arkansas' Washita stone, has a creamy white color and a hardness of about 3. Most of the other grades of stone are light gray to bluish gray in color and slightly softer than the "Washita Finish" stone. Some of the stone called "Orange Stone" has an orange tint. Occasionally the strata are colored with iron to various shades of red. Frequently alternate layers of the stone have different shades of color, giving a prettily banded structure. Sometimes the penetration of the iron laterally from the joint seams results in a banded structure running vertically through the stone instead of horizontally. The red stone is not used for whetstones, but many fancy articles are carved from it. In some layers of the stone, iron and manganese are disseminated through it in minute masses, giving it a closely speckled or peppered appearance. Dendrites of manganese sometimes occur on the surface of the whetstone strata.

STRUCTURE - Thin sections of the strongly marked varieties of the stone have been examined by microscope. The examination shows the stone to be composed of very fine quartz grains. Some of these are as small as .01mm in diameter, while the largest measured was .0325mm in diameter. The great bulk of the grains are of a nearly uniform size, averaging about .02mm in diameter. The quartz grains have generally somewhat rounded outlines, though some are distinctly angular. Some scales of mica and occasional small crystals of tourmaline are associated with the quartz grains. A few crystals of zircon and some chlorite can also occur in the stone.

Small masses of limonite are disseminated through all of the sections. In a sectioned slide of "Washita Finish" stone from the Chaillaux quarry the iron is distributed among the quartz grains in numerous small brown and black masses. In a slide of the bluish gray Hindostan from the Moore quarry the limonite is more abundant, some of it occurring in lathe-shaped masses .33mm in length by .05mm in diameter.

A thin section slide from the old Jackman quarry, one mile northwest of Roland, shows the extreme type of the ferruginous Hindostan stone. The limonite in this stone is in irregular masses, many of which are .33mm in length. These limonite masses are fringed with numerous tooth-like projections and often terminate in clusters of sharp needles.

All of the slides are somewhat clouded with earthy matter, distributed through the ground mass. This is slight in the "Washita finish" and light colored stone, but quite marked in the bluish gray stone. The cementing material seems to be the earthy matter and iron disseminated through the stone. Pieces of the stone left standing for several days in strong hydrochloric acid remained unaltered, showing that no carbonate is present as cement.

KINDS AND USES - Several different sizes and varieties of whetstones are manufactured. A class of stones intended for carpenter's and bench use is made in two sizes, viz.:

No.1 Regular, 8" x 2"-2.25" x .75"-1.50" thick

No.1 Small, 8" x 2" x .50"-1.00" thick

A white or buff stone with a smaller proportion of earthy matter than the ordinary is branded as "Washita Finish" stone and sold at a slightly higher price than No.1 Regular.

About a half-dozen different sizes and shapes of small thin stones, with rounded edges, are made and sold under the name of "slips." These are used mainly by carpenters in sharpening gouges, bedding planes and similar instruments.

A considerable number of axe stones 2.50" square by .50" thick are manufactured. These are used largely in the pine regions.

The glass-maker's file is a stone 8" long by .25" to .75" square. It is used by glass-makers in finishing glass work, and also for sharpening some kinds of tools.

The hacker stone is about 8" in length and of oval form. It is used in the turpentine regions to sharpen the broad-bladed hacker knives with which the incisions are made in the turpentine trees. About 400 gross of this stone and 40 to 50 gross of scythe stones are made annually.

The doctor stone is a large stone 4" x 4" x 2" in size, used in the calico mills to sharpen "print doctor" knives which are used to remove ink from the cylinders on which calico is printed. From 3,000 to 4,000 pounds of these are manufactured annually. "Orange Stone" is the name given to a variety of the stone having a pale orange color.

A few razor hones are manufactured, nearly all of which are sold to the visitors at French Lick and West Baden Springs.

Quick summary, I find it most interesting that the stones can range from nearly pure white, to bluish gray, to orange with or without whiter swirls, to red. They can have black or brown spots, or not. They can have manganese swirls, or not. They are a type of quite fine-grained sandstone with nearly uniform particle size of on average (in the vast majority of samples tested) about 20 microns - though they can be as small as 10 microns or as large as 32 microns.

Last edited: