It's easy to spot good steel when you find it. I have had this 7/8 Henkotsu for a while now. It always shaved well as received, but the toe needed some work. So I took it through a fast progression from 1k to an Oozuku jnat. It practically honed itself. It's when you are honing that you can really tell a lot about a steel. This one has always been a great shaver, but with the toe touched up it is right where it should be. Honing a good steel like this makes up for all the misery that comes with those 'bay finds that seem to never take an edge.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Good steel!

- Thread starter Eastcoast30

- Start date

I think there’s definitely something to this. Some razors just seem like they take better edges than others.

I have one razor that I’m convinced is a dud. It shaves but never achieves that magic edge. I’ve honed it repeatedly, raised multiple full length burrs, and tried every finisher going. Bevel angle is good, the sharpie test is good and loupe inspection is good. Never the less, the shave is always flat no matter how much you touch it up. I can only put it down to the steel or the temper.

At the same time other blades receive the same treatment and blow you away with how refined the edge becomes. The Japanese are certainly no slouch in this department.

I have one razor that I’m convinced is a dud. It shaves but never achieves that magic edge. I’ve honed it repeatedly, raised multiple full length burrs, and tried every finisher going. Bevel angle is good, the sharpie test is good and loupe inspection is good. Never the less, the shave is always flat no matter how much you touch it up. I can only put it down to the steel or the temper.

At the same time other blades receive the same treatment and blow you away with how refined the edge becomes. The Japanese are certainly no slouch in this department.

Brother @Eastcoast30 , any idea how old that blade is? I love it's look.

- Thread starter

- #4

@FarmerTan, I have not been able to find any history on Henkotsu. I do know that they rate right up there with Iwasaki and that they are of a hard and fine grain steel. I own a few and they are easily found online. But I am unable to get any history on the maker.

- Thread starter

- #5

@Tomo, I think the key to a good steel is the hardness and the grain size. I have seen the same issue with knives that are very difficult to sharpen and then lose their edge within the first use.

I certainly agree with this thread…absolutely…not all razor steels are created and/or heat treated equally.

I have a custom made razor, and unfortunately the heel develops a burr when looked at under the loupe, and the scratch pattern always looks different right under the burr down on the bevel.

I have killed the edge, set the bevel properly all along the edge, and run it through different progressions several different times…all with the same result…the final portion at the heel never responds as it should based off of my experience, and how the rest of the edge responds on this particular razor. I do wonder if the heel end got a slightly different mix of the steel or a slightly different heat treat since it was hand forged.

Speaking of high quality steel that easily takes and keeps amazing edges…I have NEVER run into a bad Filarmonica 14 from the 1st or 2nd Generations. They hone themselves like your kamisori!

Vr

Matt

I have a custom made razor, and unfortunately the heel develops a burr when looked at under the loupe, and the scratch pattern always looks different right under the burr down on the bevel.

I have killed the edge, set the bevel properly all along the edge, and run it through different progressions several different times…all with the same result…the final portion at the heel never responds as it should based off of my experience, and how the rest of the edge responds on this particular razor. I do wonder if the heel end got a slightly different mix of the steel or a slightly different heat treat since it was hand forged.

Speaking of high quality steel that easily takes and keeps amazing edges…I have NEVER run into a bad Filarmonica 14 from the 1st or 2nd Generations. They hone themselves like your kamisori!

Vr

Matt

Best example I have of a razor that "wants" to be sharp is an Ern Ator. I took it apart and deliberately killed the edge to work on it, hoping it will save some fingers. Sanding a bit, polishing a bit and when you check, the thing is ready to shave again!

On the flip side, I have two 6/8ths vintage razors, one a Crown and Sword, the other I can't remember. They both shave ok, but I have never been able to achieve the sharpness that I would expect from razors with geometry like these two.

Agree with @Matt O on Fili's. Never met one I didn't like, but even with them there are subtle differences. I get the best edges on the Sub Ceros.

On the flip side, I have two 6/8ths vintage razors, one a Crown and Sword, the other I can't remember. They both shave ok, but I have never been able to achieve the sharpness that I would expect from razors with geometry like these two.

Agree with @Matt O on Fili's. Never met one I didn't like, but even with them there are subtle differences. I get the best edges on the Sub Ceros.

That could be a topic for another thread! Which Filarmonica razors take the best edge/shave the best?Best example I have of a razor that "wants" to be sharp is an Ern Ator. I took it apart and deliberately killed the edge to work on it, hoping it will save some fingers. Sanding a bit, polishing a bit and when you check, the thing is ready to shave again!

On the flip side, I have two 6/8ths vintage razors, one a Crown and Sword, the other I can't remember. They both shave ok, but I have never been able to achieve the sharpness that I would expect from razors with geometry like these two.

Agree with @Matt O on Fili's. Never met one I didn't like, but even with them there are subtle differences. I get the best edges on the Sub Ceros.

I have/have owned and used quite a few of the models across the first two generations, and honestly I can’t choose.

I can say that the easiest one to hone from bevel set on through was my 1st GEN Doble Temple with JMP in the center of the blade face vice the lyre. It’s complete perfection!

Vr

Matt

Adding to this, I’ve had a few Doubl Ducks and they have all honed as easy as any I’ve came across. From bevel set to finish, easy.

- Thread starter

- #10

Agreed on the Fili razors. I know it is all in the steel. My minor was in metallurgical engineering, so knives and razors have always fascinated me. Matt, I suspect the heel on your blank must have missed something in the tempering process. The burr sounds like the steel is just rolling over at that spot. Maybe the grains are courser at that spot, who knows?

On the bright side, I just honed up a Red Imp that I will post for my SOTD. The back of the tang is stamped "SPECIAL RAZOR STEEL MADE FOR MORRIS MFG. CO. SOLINGEN GERMANY. And yes, this steel is special. I honed it up on my Shapton Glass stones. I recently picked up the 16k. I figured I would take it to 16k and then bring it down on a jnat. Well, I started to get HHT (not great) after 2k! After 16k I was getting "Alfredo" results. It shaved so smooth and well that I will not take it down on the jnat. BTW, I am so pleased with the Shapton Glass series that I will be selling a complete set of Naniwa SS hones.

So in the end, it's all about the steel and how it was processed. I think that is why Japanese razors are always so good. They start with good steel; hard and fine grained.

On the bright side, I just honed up a Red Imp that I will post for my SOTD. The back of the tang is stamped "SPECIAL RAZOR STEEL MADE FOR MORRIS MFG. CO. SOLINGEN GERMANY. And yes, this steel is special. I honed it up on my Shapton Glass stones. I recently picked up the 16k. I figured I would take it to 16k and then bring it down on a jnat. Well, I started to get HHT (not great) after 2k! After 16k I was getting "Alfredo" results. It shaved so smooth and well that I will not take it down on the jnat. BTW, I am so pleased with the Shapton Glass series that I will be selling a complete set of Naniwa SS hones.

So in the end, it's all about the steel and how it was processed. I think that is why Japanese razors are always so good. They start with good steel; hard and fine grained.

Poor @Eastcoast30 , and the rest of you "metal heads" in this thread!

I now know who to ask when I finally decide to learn the manly art of doing more than shave with a straight!

I knew that metal has certain "properties" but am not even an amateur when it comes to studying steel.... You Gentlemen impress me! Thank you for the information.

I now know who to ask when I finally decide to learn the manly art of doing more than shave with a straight!

I knew that metal has certain "properties" but am not even an amateur when it comes to studying steel.... You Gentlemen impress me! Thank you for the information.

rbscebu

Girls call me Makaluod

A couple of years ago I was chatting with Richard Lau of Titan Razors. He was telling me about developing the steel for their ACRO blade SR's with their Japanese steel maker. They were aiming for a very hard (close to 70 RHC) steel with small grain size and strong intergranular bonding in a martensitic type stainless steel.

Not an easy development to achieve. They did eventually achieve their aims. The hardness was no great problem. The small grain size took some work. The hardest part was achieving good intergranular bonding so that the edge would not chip so easily when honing.

Not an easy development to achieve. They did eventually achieve their aims. The hardness was no great problem. The small grain size took some work. The hardest part was achieving good intergranular bonding so that the edge would not chip so easily when honing.

- Thread starter

- #13

I can appreciate the difficulties. Martensite grain structure is an irregular tetrahedron and very fine so it remains strong with very few slip planes. But while martensite is hard, 70 HRC is extra hard, and martensite is known to be brittle. That's the main problem with hardness. Too soft won't hold an edge and too hard is brittle. The middle ground is the characteristic known as "toughness". So don't drop that Titan!

rbscebu

Girls call me Makaluod

I now my Titan ACRO T.H-70 SR's like they are made of glass.I can appreciate the difficulties. Martensite grain structure is an irregular tetrahedron and very fine so it remains strong with very few slip planes. But while martensite is hard, 70 HRC is extra hard, and martensite is known to be brittle. That's the main problem with hardness. Too soft won't hold an edge and too hard is brittle. The middle ground is the characteristic known as "toughness". So don't drop that Titan!

I remember my first Titan ACRO. I broke that blade while stropping. I was still new to stropping and didn't appreciate how delicate some steel's could be when so hard and thin. Fortunately Titan replaced that SR for free.

Same experience with the Ducks. They almost hone themselvesAdding to this, I’ve had a few Doubl Ducks and they have all honed as easy as any I’ve came across. From bevel set to finish, easy.

The only steel that I've seen claimed on tang stamps

when the razor was made in a different country

from where the steel came from,

is Swedish steel.

when the razor was made in a different country

from where the steel came from,

is Swedish steel.

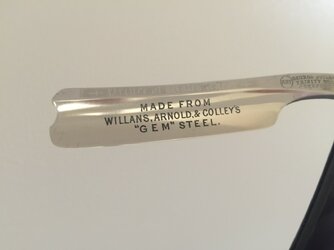

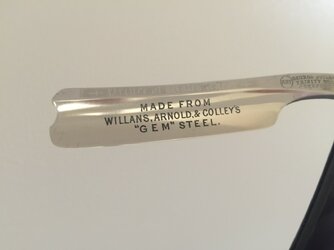

These two were a bit of a mystery to me. On the top of the spine "Prince of Wales Razor" is etched. I bought this pair, and I tried to find information about the "GEM" steel. I could not find any information, but it was probably just some marketing scheme at the time. If the steel was something special, it would probably be better known.

Honed very easily, and as you can see it has a very thin bevel. Shaves nice, but I prefer thinner grinds.

Honed very easily, and as you can see it has a very thin bevel. Shaves nice, but I prefer thinner grinds.

Last edited:

I have one razor whose steel was cryogenically hardened. Apparently, if done right, this can produce a fantastic razor. In the case of the razor I own, everytime I get the edge keen enough, the edge crumbles (microchipping) and I cannot shave with the razor withough tearing up my face. I have tried a lot of different hones and a lot of different techniques. Nothing has worked. I have honed with tape and without tape. I have tried producing a double bevel. Nope! Not happening! Like Thomas Edison, I now know many things that don't work. A straight razor made from great steel, well ground and properly hardened is a delight to the eyes and to the face.

Similar threads

- Replies

- 14

- Views

- 990

- Replies

- 40

- Views

- 3K

- Replies

- 8

- Views

- 680