Hello everyone,

I decided to once again try and learn how to hone. I am in need of asistance from you - experienced honers - on how to read the razor and determine what it needs. I won't be doing countles laps on the stone like before without knowing what needs to be done. If it doesn't go well after a few laps and it feels off - I'll stop, think and ask questions. Any help in this thread will be greatly appreciated. I will be posting all sorts of pictures and my thoughts about them. If you could provide any tips and thoughts, I'm sure it will help me progress faster.

My setup:

Naniwa superstones: 1k, 3k, 5k, 8k, 12k

Lapping: Diamond stone 150/600

Cheap loupe with LED saying it's 10x-25x

Cheap ebay "microscope" "1600x" (it's not a microscope and it's not 1600x... but you know what I'm talking about.)

I don't want to spend a dime more on my setup. I have to make do with what I have. I have poured too much into it already and I'm not yielding any results.

Current status of the SR in question.

So, I purchased a GD 66 for 4€ to learn about honing. I'm NOT afraid to trash this razor in order to learn at least something.

It has a smile edge, so I'm training rolling X strokes. I've put a lot of hone wear on the spine. I modified the heel to move the cornen of the heel away from the stabilizer, in order to stop honing on the stabilizer and lifting the edge from the stone. I think at some point in the past I have used tape, so when I did a few laps today I created a double bevel.

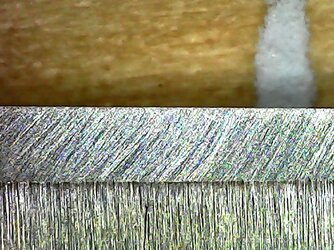

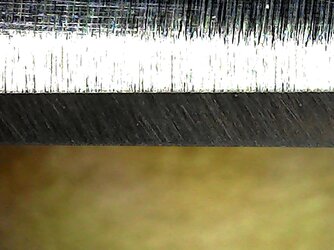

Sharpie test revealed that I'm not hitting full spine and bevel from the first lap. After 5 laps, all the sharpie is gone, but that is because I adjusted my stroke after looking at the state of the sharpie after each lap. Microscope picture reveals a double bevel - I think? Notice the difference in the stria at the top of the picture (edge is at the top). Can't see it with the loupe so, I'm not sure.

Here is the microscope picture: (your thoughts on the state of the razor and what it needs greatly appreciated)

I decided to once again try and learn how to hone. I am in need of asistance from you - experienced honers - on how to read the razor and determine what it needs. I won't be doing countles laps on the stone like before without knowing what needs to be done. If it doesn't go well after a few laps and it feels off - I'll stop, think and ask questions. Any help in this thread will be greatly appreciated. I will be posting all sorts of pictures and my thoughts about them. If you could provide any tips and thoughts, I'm sure it will help me progress faster.

My setup:

Naniwa superstones: 1k, 3k, 5k, 8k, 12k

Lapping: Diamond stone 150/600

Cheap loupe with LED saying it's 10x-25x

Cheap ebay "microscope" "1600x" (it's not a microscope and it's not 1600x... but you know what I'm talking about.)

I don't want to spend a dime more on my setup. I have to make do with what I have. I have poured too much into it already and I'm not yielding any results.

Current status of the SR in question.

So, I purchased a GD 66 for 4€ to learn about honing. I'm NOT afraid to trash this razor in order to learn at least something.

It has a smile edge, so I'm training rolling X strokes. I've put a lot of hone wear on the spine. I modified the heel to move the cornen of the heel away from the stabilizer, in order to stop honing on the stabilizer and lifting the edge from the stone. I think at some point in the past I have used tape, so when I did a few laps today I created a double bevel.

Sharpie test revealed that I'm not hitting full spine and bevel from the first lap. After 5 laps, all the sharpie is gone, but that is because I adjusted my stroke after looking at the state of the sharpie after each lap. Microscope picture reveals a double bevel - I think? Notice the difference in the stria at the top of the picture (edge is at the top). Can't see it with the loupe so, I'm not sure.

Here is the microscope picture: (your thoughts on the state of the razor and what it needs greatly appreciated)

Last edited: