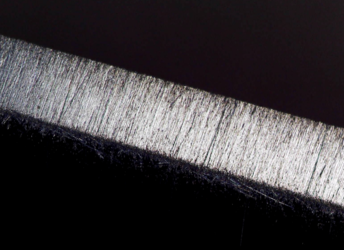

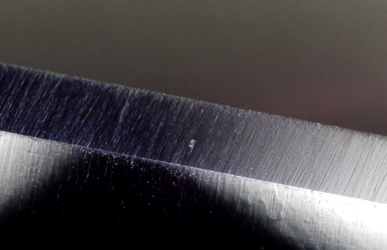

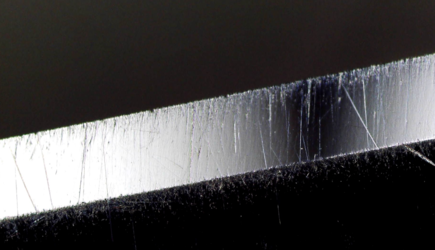

Yes, bevels are not meeting fully, and lots of deep 1k stria that end in a microchip.

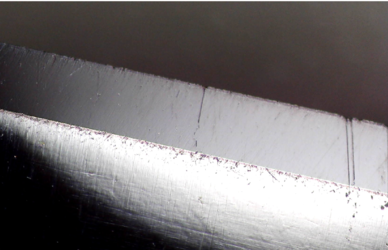

In the second photo from the side of the bevel looks like a large burr formation on the right side.

Joint the edge, a single lite stroke on the stone face to remove the burr and straighten the edge. Then reset the bevel with the 4k until all the deep and random stria are gone and a uniform 4k stria pattern and fully edge meeting are formed. Then remove the 4k stria with the 8k.

The 4k stone, where you transition from grinding to polishing is probably your most important stone. If you do not get all the deep stria out and get the bevels meeting fully, the edge will fight you all the way.

This is a common new honer problem.

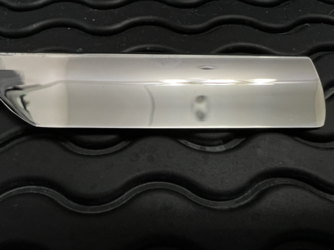

Post a photo of the whole blade from the side, you may have other issues that need attention.

In the second photo from the side of the bevel looks like a large burr formation on the right side.

Joint the edge, a single lite stroke on the stone face to remove the burr and straighten the edge. Then reset the bevel with the 4k until all the deep and random stria are gone and a uniform 4k stria pattern and fully edge meeting are formed. Then remove the 4k stria with the 8k.

The 4k stone, where you transition from grinding to polishing is probably your most important stone. If you do not get all the deep stria out and get the bevels meeting fully, the edge will fight you all the way.

This is a common new honer problem.

Post a photo of the whole blade from the side, you may have other issues that need attention.