You may have heard that breadknifing your straight razor removes more material than just honing out the defects with lower grits and "traditional" or "normal" honing strokes. The debate whether it does or does not remove more material seems to be going on to this day. This "study" and simulation will prove, theoretically that the process of breadknifing with honing done afterwards removes the same amount of steel as if you would hone the defect away without breadknifing.

In this study I have proved that breadknifing a straight razor is not a waste of steel AT ALL.

Sure we could argue that you could flatten the edge too much, removing more material than is needed. But just as easily you could remove the frown with "normal" honing and forget to check if the edge is straight. Lost in thought, meditating while you hone away, your edge could have been straight and the bevel was set 50 laps ago. You are probably on a grit lower than 1k, so your steel loss will be the same as mine, if I over-do it on the breadknifing.

The only question is: who will have more patience to check for the straightness of the edge often enough to catch a perfect moment of a straight edge with zero steel wasted. And I could tell that I will stop breadknifing a little early and swith to 1k honing until the edge is straight and the bevel is set, losing zero steel in the process of breadknifing. I am also already at 1k with a bevel set, while you are still on 400 trying to remove the frown and get a straight edge. Now remember, you still have to get to 1k and remove 400 stria.

So therefore, it is my opinion that breadknifing with care is a time saver. I am not a patient man. Is it for everybody? Who am I to tell anyobody what gear to buy and what to do with their razors? I will do with mine as I see fit and good luck to everybody with their own blades. Let's all share the things we have learned while we spent quality time, deep in our beloved hobby.

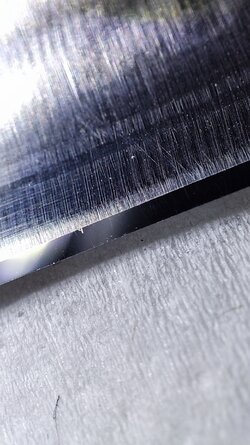

But I'm confident and I have proof that breadknifing is not a waste of steel, at all. Please see the attachment for some cool pictures and let's consider this as an end to the debate on this topic. Share with anyone who is not sure about breadknifing. This is all you will need in terms of theory behind the amount of steel removed by this method compared to "normal" honing. Sure, real life situations are not perfect, our hand-eye coordination is not perfect. But breadknifing can be done without ZERO steel loss and here is why.

In this study I have proved that breadknifing a straight razor is not a waste of steel AT ALL.

Sure we could argue that you could flatten the edge too much, removing more material than is needed. But just as easily you could remove the frown with "normal" honing and forget to check if the edge is straight. Lost in thought, meditating while you hone away, your edge could have been straight and the bevel was set 50 laps ago. You are probably on a grit lower than 1k, so your steel loss will be the same as mine, if I over-do it on the breadknifing.

The only question is: who will have more patience to check for the straightness of the edge often enough to catch a perfect moment of a straight edge with zero steel wasted. And I could tell that I will stop breadknifing a little early and swith to 1k honing until the edge is straight and the bevel is set, losing zero steel in the process of breadknifing. I am also already at 1k with a bevel set, while you are still on 400 trying to remove the frown and get a straight edge. Now remember, you still have to get to 1k and remove 400 stria.

So therefore, it is my opinion that breadknifing with care is a time saver. I am not a patient man. Is it for everybody? Who am I to tell anyobody what gear to buy and what to do with their razors? I will do with mine as I see fit and good luck to everybody with their own blades. Let's all share the things we have learned while we spent quality time, deep in our beloved hobby.

But I'm confident and I have proof that breadknifing is not a waste of steel, at all. Please see the attachment for some cool pictures and let's consider this as an end to the debate on this topic. Share with anyone who is not sure about breadknifing. This is all you will need in terms of theory behind the amount of steel removed by this method compared to "normal" honing. Sure, real life situations are not perfect, our hand-eye coordination is not perfect. But breadknifing can be done without ZERO steel loss and here is why.