Had a problem roasting coffee this weekend. I loaded the wire mesh drum with beans in preparation for roasting in my Behmor 1600. I usually give it a vigorous shake and few rotations by hand to coax out any of the small beans (imperfections) before inserting into the roaster. Usually a couple of beans/particles shake loose, but this time I was surprised to see dozens of beans flying around. Upon close inspection I saw that one of the agitating fins had broken away from the wire mesh and was folded into the drum. Rather than stop and repair it, I just folded back into shape and went ahead with the roast. Only lost 10-20 beans during the roast, so that aspect of the day turned out okay.

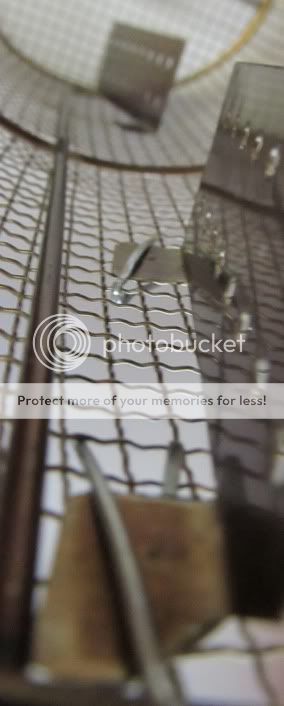

A few pictures of the damage. Might be difficult to see clearly, especially if you are not a Behmor user.

Same picture angle as above, this time with a white piece of paper inserted behind the fin to highlight the failure:

View from the top. Can see the hole on the right side along with the dangling fin:

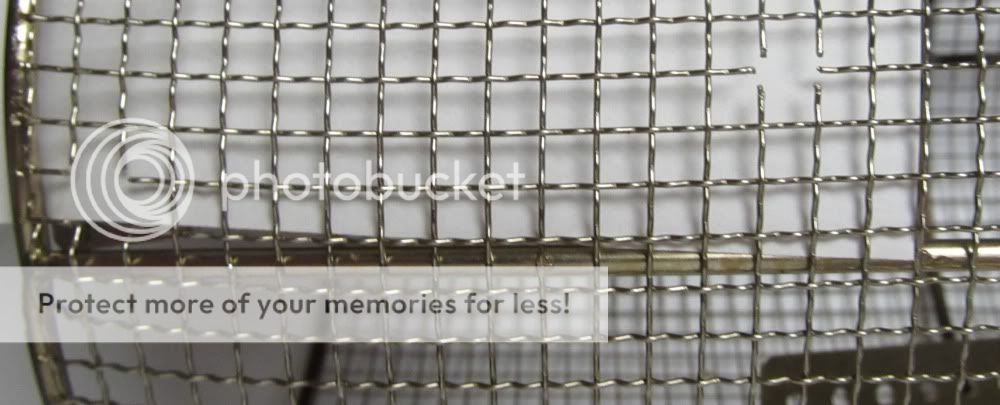

A few pictures of the damage. Might be difficult to see clearly, especially if you are not a Behmor user.

Same picture angle as above, this time with a white piece of paper inserted behind the fin to highlight the failure:

View from the top. Can see the hole on the right side along with the dangling fin: