Jim on your SS General yes you only need do the top cap and if you like the SB part of the razor that touches the face. Flitz is good so no worries there. If I were you I'd keep my eyes open for a Brass General. They do come up now and then in the BST section and also online. Buy it and sell the SS or if budget allows keep both. SS is less maintenance for sure and the manufacture knows that and probably decided to appeal to the masses. If it were me I'd offer both and the Brass as a premium model and the Aluminum as the entry level. Choice is always nice for the buyer. I don't think the metal makes a hoot of a difference to a machine shop that manufactures or works with a lot of different metals. Also a lot of machine shops that make razors also do other items not just razors. Timeless is a good example of that.You mean buff it by hand, right?

Thanks so much. I'll see what the Flitz does (since I have it), and consider ordering one or two of the others. Please compare them for us when you have both if you can.

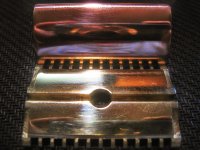

You're polishing just the top of the cap? What else? I know the top surface of the razor (the cap and maybe the top surface of the guard) is all that needs to be polished for a functional (gliding better) purpose.

Like you, I wish the brass General had not been discontinued. I wonder what the advantage of SS over brass is supposed to be, for either the end user or the manufacturer. SS is harder, but look how long vintage brass (plated usually) razors sold for a dollar have lasted.

It might be that machine shops, large and small, are more used to working with SS. That's a flat out guess - no knowledge, no data, no experience, and no research - at best.

Happy shaves,

Jim

Hope that helps and great shaves right back at ya!

Frank