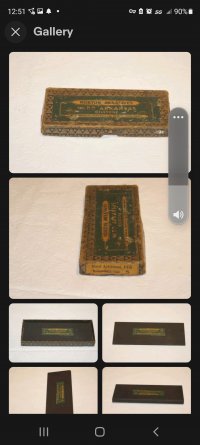

My smallest and my largest

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Arkansas Love...Let's see those Arks!

- Thread starter David

- Start date

The hardware store is still out of WD but I found an ample supply at the car supply shop. I’m slowly clearing the backlog.

I managed to get both sides of this vintage black Norton flat but I ran out of time before I was able to take it up the progression. An absolutely beautiful stone is starting to take shape. The label came off cleanly before starting after soaking the stone in water.

Today is a draw. We will play again tomorrow.

My method is.

1. Start at 240 WD on a granite surface plate. Checking for flatness by removing pencil grids.

2. Add loose SIC to the WD surface if work is required.

3. Continue until flat. Replacing paper periodically

4. Use clean 240 WD to check that pencil grids are removed easily and evenly before slurry builds up.

5. Check reflection is even in all areas with no dull patches in the surface.

6. Once good go up 2x320, 2x400, 2x600 and 2x800 WD sheets each side. Checking that pencil grids come off easily and evenly. The first sheet gets worked pretty hard. The second sheet gets lighter pressure until a bit swarf builds up.

7. Burnish both sides well with a chisel.

8. Rough up both sides with 2x1000 WD sheets

9. Burnish the polished side with a chisel. Lap the polished side on another polished ark.

10. Lightly lap the matt side with a chisel.

Step 1 Photo

I managed to get both sides of this vintage black Norton flat but I ran out of time before I was able to take it up the progression. An absolutely beautiful stone is starting to take shape. The label came off cleanly before starting after soaking the stone in water.

Today is a draw. We will play again tomorrow.

My method is.

1. Start at 240 WD on a granite surface plate. Checking for flatness by removing pencil grids.

2. Add loose SIC to the WD surface if work is required.

3. Continue until flat. Replacing paper periodically

4. Use clean 240 WD to check that pencil grids are removed easily and evenly before slurry builds up.

5. Check reflection is even in all areas with no dull patches in the surface.

6. Once good go up 2x320, 2x400, 2x600 and 2x800 WD sheets each side. Checking that pencil grids come off easily and evenly. The first sheet gets worked pretty hard. The second sheet gets lighter pressure until a bit swarf builds up.

7. Burnish both sides well with a chisel.

8. Rough up both sides with 2x1000 WD sheets

9. Burnish the polished side with a chisel. Lap the polished side on another polished ark.

10. Lightly lap the matt side with a chisel.

Step 1 Photo

Last edited:

I'm ready to order a true hard, I love how they look. I just have a hard time justifying buying a brand new hone right now.My smallest and my largest View attachment 1335004

A very beautiful stone has found it’s way into my collection. I’m still pinching myself. It’s a stunner complete with box and labels.

Now that the WD drought is over, I’ve finally got it lapped and prepped. It’s a very consistent, very dense, semi translucent, vintage, Behr-Manning Norton Hard Arkansas.

I’m quite certain that is will make an excellent finisher. It also makes a perfect bookend for my Vintage HB26 Trans Bear Norton. The stone is current finished to 800 grit WD.

Now that the WD drought is over, I’ve finally got it lapped and prepped. It’s a very consistent, very dense, semi translucent, vintage, Behr-Manning Norton Hard Arkansas.

I’m quite certain that is will make an excellent finisher. It also makes a perfect bookend for my Vintage HB26 Trans Bear Norton. The stone is current finished to 800 grit WD.

Attachments

-

63941027-09B0-4428-9C42-C0FED8E29AD2.jpeg5.8 MB · Views: 28

63941027-09B0-4428-9C42-C0FED8E29AD2.jpeg5.8 MB · Views: 28 -

F6B9B4FB-8D0F-4A89-A9FE-BA6C1D39098D.jpeg5.6 MB · Views: 28

F6B9B4FB-8D0F-4A89-A9FE-BA6C1D39098D.jpeg5.6 MB · Views: 28 -

981BDDA4-1BEE-4483-BD15-152DD2350175.jpeg1.9 MB · Views: 25

981BDDA4-1BEE-4483-BD15-152DD2350175.jpeg1.9 MB · Views: 25 -

AC403F19-D26C-460E-A4A3-D754A7117C56.jpeg5.3 MB · Views: 28

AC403F19-D26C-460E-A4A3-D754A7117C56.jpeg5.3 MB · Views: 28 -

9962F5D7-2E92-44E4-A00D-95D68E83D349.jpeg5.9 MB · Views: 36

9962F5D7-2E92-44E4-A00D-95D68E83D349.jpeg5.9 MB · Views: 36 -

4DD87D08-9FE0-4885-AA74-0E74ACB91DA8.jpeg6.2 MB · Views: 36

4DD87D08-9FE0-4885-AA74-0E74ACB91DA8.jpeg6.2 MB · Views: 36

Last edited:

timwcic

"Look what I found"

I’m quite certain that is will make an excellent finisherView attachment 1335695

WOW!! Those dark translucent are fabulous finishers. Heirloom stone

- Thread starter

- #886

Very nice score. Those green label black Arks are very rare and from the ones I’ve used are stellar performers.A very beautiful stone has found it’s way into my collection. I’m still pinching myself. It’s a stunner complete with box and labels.

Now that the WD drought is over, I’ve finally got it lapped and prepped. It’s a very consistent, very dense, semi translucent, vintage, Behr-Manning Norton Hard Arkansas.

I’m quite certain that is will make an excellent finisher. It also makes a perfect bookend for my Vintage HB26 Trans Bear Norton. The stone is current finished to 800 grit WD.

View attachment 1335695

My latest purchase from Dan’s arrived today. 8x2.5x0.5” soft ark and 6x2x0.5

The soft is my first labeled soft. Interested to see how IG compares to the few Washita that I have. The true hard wasn’t entirely needed, I have an 8x2 black ark, but… my excuse is that I was looking for a smaller stone for hand honing. And then I told myself “look how much money you are saving by not going for a translucent!” The grey areas are very translucent , the white areas not at all.

The grey areas are very translucent , the white areas not at all.

The soft is my first labeled soft. Interested to see how IG compares to the few Washita that I have. The true hard wasn’t entirely needed, I have an 8x2 black ark, but… my excuse is that I was looking for a smaller stone for hand honing. And then I told myself “look how much money you are saving by not going for a translucent!”

Let me know how you like that soft. I've been considering getting a big one to rough up a lot on one side and smooth the other a little for big knives but I've heard wildly different things about Dan's soft stones. I've got numerous stone from him they are all just finishers. Im going to get them to cut me a combo stone with a tweener or super soft on one side and a true hard on the other(I love their look) cut 4" or 5" x 1.5"x 1" height from the combined stones. The people there are amazing and Kim had the patience of a saint because she gets lots of emails from me this week. I buy the leather pouches and all kinds of stuff from them. They'll custom make anything(pretty reasonably at that) and everything I've gotten from them has been the only new products I've purchased that rival the antique stones I've got. That level of aerial control just isn't in the world anymore except from small family businesses and independent artisans.My latest purchase from Dan’s arrived today. 8x2.5x0.5” soft ark and 6x2x0.5

The soft is my first labeled soft. Interested to see how IG compares to the few Washita that I have. The true hard wasn’t entirely needed, I have an 8x2 black ark, but… my excuse is that I was looking for a smaller stone for hand honing. And then I told myself “look how much money you are saving by not going for a translucent!”The grey areas are very translucent , the white areas not at all.

View attachment 1338744View attachment 1338745

My latest purchase from Dan’s arrived today. 8x2.5x0.5” soft ark and 6x2x0.5

The soft is my first labeled soft. Interested to see how IG compares to the few Washita that I have. The true hard wasn’t entirely needed, I have an 8x2 black ark, but… my excuse is that I was looking for a smaller stone for hand honing. And then I told myself “look how much money you are saving by not going for a translucent!”The grey areas are very translucent , the white areas not at all.

View attachment 1338744View attachment 1338745

Report back on the true hard stone. Looks a lot like my 10”x2”. They are nice stones.

I've heard pretty consistent reports that they are awesome. I bought another unnecessary slip stone today. It's a norton hard arkansas but it's 5" x 1 7/8" and instead of translucent it's black. I've never seen a black norton slip much less one in 5" x 2"(essentially). Crazy stuff. It was $29 + shipping and I know the chances of finding a quality stone, that really needs no work,glassy, flat stone for that new off the shelves today it's just about 0.Report back on the true hard stone. Looks a lot like my 10”x2”. They are nice stones.

OK, so here’s a question for the audience. I have a few midlevel stones acquired recently, some Washita (in some cases maybe soft Ark called Washita), and a soft Ark.

I have an idea that one can judge a bevel setter by how fast it cuts metal or generates swarf. And one can judge a finisher by the sharpness and smoothness of the shave. But how does one judge the performance of a mid-level stone - the guy that comes after the bevel setter and before the finisher? To some extent I would think it gets very subjective - how does that stone fit into the progression based on the other stones that already are part of the progression? Or are there other criteria, for example whether this one mid-level stone can replace two others (e.g. a 5k and an 8k)?

I have an idea that one can judge a bevel setter by how fast it cuts metal or generates swarf. And one can judge a finisher by the sharpness and smoothness of the shave. But how does one judge the performance of a mid-level stone - the guy that comes after the bevel setter and before the finisher? To some extent I would think it gets very subjective - how does that stone fit into the progression based on the other stones that already are part of the progression? Or are there other criteria, for example whether this one mid-level stone can replace two others (e.g. a 5k and an 8k)?

With a washita you should be able to set a bevel and take it almost all the way with that one. It's why stone people love them so much because they can take the place of 3 or 4 stones. I've got soft arks and "new washitas" that can do the same just a little slower(in some cases) if you pay attention to surface prep and keep grit off the surface I think you'll be surprised at the range that those rocks have.OK, so here’s a question for the audience. I have a few midlevel stones acquired recently, some Washita (in some cases maybe soft Ark called Washita), and a soft Ark.

I have an idea that one can judge a bevel setter by how fast it cuts metal or generates swarf. And one can judge a finisher by the sharpness and smoothness of the shave. But how does one judge the performance of a mid-level stone - the guy that comes after the bevel setter and before the finisher? To some extent I would think it gets very subjective - how does that stone fit into the progression based on the other stones that already are part of the progression? Or are there other criteria, for example whether this one mid-level stone can replace two others (e.g. a 5k and an 8k)?

OK, so initial impression on a few newly acquired stones.

Yesterday I worked a progression on a razor that I had purchased at a flea market - a Henkels Platinum 401, which is a carbon steel blade. It was already in great shape - it passed the tomato cutting pass from the beginning, but wouldn’t tree-top. So not a real test from a bevel-setting perspective.

I also did some measurements to determine specific gravity on my Arkansas stones:

Stone S.G.

Pike LLW. . 2.16 vintage, newly acquired and cleaned (somewhat)

Dan’s Soft Ark. 2.17 newly acquired

Dan’s hard Ark. 2.47 Had for some time, not used much

Dan’s black Ark. 2.64 Had for some time, my usual finisher

Dan’s true hard. 2.63 Newly acquired

For what it is worth Dan’s has the following ranges on its website:

Washita. < 2.25 (to Dan’s a Washita is just a softer Soft Ark)

Soft Ark. 2.25 - 2.30

Hard Ark. 2.30 - 2.45

True Hard Ark. > 2.5

So it appears that my Soft Ark is pretty soft, my hard Ark is at the top of the range, and my two “true hard” arks easily clear the cut-off and are also nearly identical. Also my Soft Ark is nearly identical to my Washita from an S.G. perspective.

For this run I started with the Washita, then went to the hard Ark followed by the true hard. I used Norton honing oil on all 3 stones. I followed a similar stroke progression, edge-leading X-strokes until I thought the razor had settled in, then spine-leading strokes, a few pull strokes and finally a few short spine-leading X-strokes.

Note that in the past I have honed many razors with a mostly synthetic progression, but ending with an ILR and the black Ark. I have gotten some very sharp edges out of this, but the feel was always a bit harsh. This is always removed if I follow up with a 0.5/0.25/0.1u diamond-pasted balsa progression. So the balsa progression always improves the comfort, even if it doesn’t make the razor feel sharper. Over time the harshness has gotten less and less, but in 8 or so tries, I’ve never believed that I didn’t feel at least some comfort improvement from applying the pasted balsa.

A few things were different this time. 1) The true hard was used exactly as it had come from Dan’s, which is a relatively rough finish (200 grit?). My black Ark is currently finished to 600 grit. 2) The True Hard showed swarf after it had worked awhile. I don’t recall ever seeing swarf on my hard or black Arkansas. In fairness, if you look at the photos below, it would be really hard to actually see swarf on my hard Ark and my black Ark (not shown) is even worse. 3) This morning’s shave felt both sharp AND smooth. I love my black Ark and I was convinced that the best I could hope for from the true hard was to match its performance, but I think it actually beat it. In fairness, it might have something to do with the setup (or the razor). So worth exploring further.

Also want to spend some time comparing the Soft Ark to the Washita. May play with this using some of my 2nd tier steak knives initially, then come up with a more challenging bevel setting test then what was faced today.

Yesterday I worked a progression on a razor that I had purchased at a flea market - a Henkels Platinum 401, which is a carbon steel blade. It was already in great shape - it passed the tomato cutting pass from the beginning, but wouldn’t tree-top. So not a real test from a bevel-setting perspective.

I also did some measurements to determine specific gravity on my Arkansas stones:

Stone S.G.

Pike LLW. . 2.16 vintage, newly acquired and cleaned (somewhat)

Dan’s Soft Ark. 2.17 newly acquired

Dan’s hard Ark. 2.47 Had for some time, not used much

Dan’s black Ark. 2.64 Had for some time, my usual finisher

Dan’s true hard. 2.63 Newly acquired

For what it is worth Dan’s has the following ranges on its website:

Washita. < 2.25 (to Dan’s a Washita is just a softer Soft Ark)

Soft Ark. 2.25 - 2.30

Hard Ark. 2.30 - 2.45

True Hard Ark. > 2.5

So it appears that my Soft Ark is pretty soft, my hard Ark is at the top of the range, and my two “true hard” arks easily clear the cut-off and are also nearly identical. Also my Soft Ark is nearly identical to my Washita from an S.G. perspective.

For this run I started with the Washita, then went to the hard Ark followed by the true hard. I used Norton honing oil on all 3 stones. I followed a similar stroke progression, edge-leading X-strokes until I thought the razor had settled in, then spine-leading strokes, a few pull strokes and finally a few short spine-leading X-strokes.

Note that in the past I have honed many razors with a mostly synthetic progression, but ending with an ILR and the black Ark. I have gotten some very sharp edges out of this, but the feel was always a bit harsh. This is always removed if I follow up with a 0.5/0.25/0.1u diamond-pasted balsa progression. So the balsa progression always improves the comfort, even if it doesn’t make the razor feel sharper. Over time the harshness has gotten less and less, but in 8 or so tries, I’ve never believed that I didn’t feel at least some comfort improvement from applying the pasted balsa.

A few things were different this time. 1) The true hard was used exactly as it had come from Dan’s, which is a relatively rough finish (200 grit?). My black Ark is currently finished to 600 grit. 2) The True Hard showed swarf after it had worked awhile. I don’t recall ever seeing swarf on my hard or black Arkansas. In fairness, if you look at the photos below, it would be really hard to actually see swarf on my hard Ark and my black Ark (not shown) is even worse. 3) This morning’s shave felt both sharp AND smooth. I love my black Ark and I was convinced that the best I could hope for from the true hard was to match its performance, but I think it actually beat it. In fairness, it might have something to do with the setup (or the razor). So worth exploring further.

Also want to spend some time comparing the Soft Ark to the Washita. May play with this using some of my 2nd tier steak knives initially, then come up with a more challenging bevel setting test then what was faced today.

“Anybody ever heard of these guys? Fantastic little black semi translucent, seems to be a really high quality hard(old hard) arkansas. I bought it because it's 4x1.5 which I like I wish it was a 0.25" thicker though.”

Ha!

Russell’s, as in AG Russell’s?

A.G. Russell founder of A. G. Russell Knives started out selling Arks, He would go to the gun shows in the late 60 and 70’s, (there were no “knife shows” in those days) and lay out tables of stones and a hand full of knives.

He started production knife making, responsible for Knife shows, most of the knife magazines, some say he is the reason folks collect knives today. Was the first member of the Knife Digest Cutlery Hall of Fame and co-founded the Knife Collectors Club and the Knifemakers' Guild.

I carried one of his boot knives for years and have several Arks that I bought from him personally back in the day, one an 11X3 inch black finisher. He was a gregarious guy and love to talk knives and honing. He got me started honing razors, chasing the ultimate knife edge back in the 70’s.

Yea, I think you got a good stone there.

Don't touch it, do not lap it, until you put a razor on it with some oil, Smiths or Ballistol. Chances are it will not need a thing to produce a super edge.

Enjoy

Ha!

Russell’s, as in AG Russell’s?

A.G. Russell founder of A. G. Russell Knives started out selling Arks, He would go to the gun shows in the late 60 and 70’s, (there were no “knife shows” in those days) and lay out tables of stones and a hand full of knives.

He started production knife making, responsible for Knife shows, most of the knife magazines, some say he is the reason folks collect knives today. Was the first member of the Knife Digest Cutlery Hall of Fame and co-founded the Knife Collectors Club and the Knifemakers' Guild.

I carried one of his boot knives for years and have several Arks that I bought from him personally back in the day, one an 11X3 inch black finisher. He was a gregarious guy and love to talk knives and honing. He got me started honing razors, chasing the ultimate knife edge back in the 70’s.

Yea, I think you got a good stone there.

Don't touch it, do not lap it, until you put a razor on it with some oil, Smiths or Ballistol. Chances are it will not need a thing to produce a super edge.

Enjoy

I want one those true hard stones so bad, they look awesome. I've been considering asking Kim if they'd cut a roughly 5x1x1 primitive cut of it. I know translucents have more teeth and a borderline translucent should have more. I figured it be awesome a a quick finisher for knives at work(because I don't carry 4 finishing stones with me already....)OK, so initial impression on a few newly acquired stones.

Yesterday I worked a progression on a razor that I had purchased at a flea market - a Henkels Platinum 401, which is a carbon steel blade. It was already in great shape - it passed the tomato cutting pass from the beginning, but wouldn’t tree-top. So not a real test from a bevel-setting perspective.

I also did some measurements to determine specific gravity on my Arkansas stones:

Stone S.G.

Pike LLW. . 2.16 vintage, newly acquired and cleaned (somewhat)

Dan’s Soft Ark. 2.17 newly acquired

Dan’s hard Ark. 2.47 Had for some time, not used much

Dan’s black Ark. 2.64 Had for some time, my usual finisher

Dan’s true hard. 2.63 Newly acquired

For what it is worth Dan’s has the following ranges on its website:

Washita. < 2.25 (to Dan’s a Washita is just a softer Soft Ark)

Soft Ark. 2.25 - 2.30

Hard Ark. 2.30 - 2.45

True Hard Ark. > 2.5

So it appears that my Soft Ark is pretty soft, my hard Ark is at the top of the range, and my two “true hard” arks easily clear the cut-off and are also nearly identical. Also my Soft Ark is nearly identical to my Washita from an S.G. perspective.

For this run I started with the Washita, then went to the hard Ark followed by the true hard. I used Norton honing oil on all 3 stones. I followed a similar stroke progression, edge-leading X-strokes until I thought the razor had settled in, then spine-leading strokes, a few pull strokes and finally a few short spine-leading X-strokes.

Note that in the past I have honed many razors with a mostly synthetic progression, but ending with an ILR and the black Ark. I have gotten some very sharp edges out of this, but the feel was always a bit harsh. This is always removed if I follow up with a 0.5/0.25/0.1u diamond-pasted balsa progression. So the balsa progression always improves the comfort, even if it doesn’t make the razor feel sharper. Over time the harshness has gotten less and less, but in 8 or so tries, I’ve never believed that I didn’t feel at least some comfort improvement from applying the pasted balsa.

A few things were different this time. 1) The true hard was used exactly as it had come from Dan’s, which is a relatively rough finish (200 grit?). My black Ark is currently finished to 600 grit. 2) The True Hard showed swarf after it had worked awhile. I don’t recall ever seeing swarf on my hard or black Arkansas. In fairness, if you look at the photos below, it would be really hard to actually see swarf on my hard Ark and my black Ark (not shown) is even worse. 3) This morning’s shave felt both sharp AND smooth. I love my black Ark and I was convinced that the best I could hope for from the true hard was to match its performance, but I think it actually beat it. In fairness, it might have something to do with the setup (or the razor). So worth exploring further.

Also want to spend some time comparing the Soft Ark to the Washita. May play with this using some of my 2nd tier steak knives initially, then come up with a more challenging bevel setting test then what was faced today.

View attachment 1339909View attachment 1339912

It's a fantastic stone stone and I try my best to not lap finishers I pick up unless I must. It's different from other blacks I've had but it's great. It seems like it would be a "translucent black?" But it doesn't transmit light really. I with it was 1/2 but I like. To be honest I wish it was 8x2x1 but you know, what can you do. I like small stones and I've found a lot of time you can get extremely high quality stones for almost nothing. It why I love buying dirty washitas.“Anybody ever heard of these guys? Fantastic little black semi translucent, seems to be a really high quality hard(old hard) arkansas. I bought it because it's 4x1.5 which I like I wish it was a 0.25" thicker though.”

Ha!

Russell’s, as in AG Russell’s?

A.G. Russell founder of A. G. Russell Knives started out selling Arks, He would go to the gun shows in the late 60 and 70’s, (there were no “knife shows” in those days) and lay out tables of stones and a hand full of knives.

He started production knife making, responsible for Knife shows, most of the knife magazines, some say he is the reason folks collect knives today. Was the first member of the Knife Digest Cutlery Hall of Fame and co-founded the Knife Collectors Club and the Knifemakers' Guild.

I carried one of his boot knives for years and have several Arks that I bought from him personally back in the day, one an 11X3 inch black finisher. He was a gregarious guy and love to talk knives and honing. He got me started honing razors, chasing the ultimate knife edge back in the 70’s.

Yea, I think you got a good stone there.

Don't touch it, do not lap it, until you put a razor on it with some oil, Smiths or Ballistol. Chances are it will not need a thing to produce a super edge.

Enjoy

It’s a combination black and translucent stone, I have a black with translucent streaks running through it. A few years ago, folks were calling them Translucent Grey stones. They can produce the same finish as a Surgical Black or Translucent.

People have opinions about Blacks and Translucent, but most of that, is marketing hype. To get the most from a hard ark you must have a well finished 10-12 k edge, some 8k’s will work, or a smooth Washita, which is where the 600 step helps to finish, because the burnished will not cut and only polish.

I have several vintage Blacks and Translucent, and the grey, I believe they are capable of producing the same quality edge.

I say not to lap it because if it was well used, it has tons of time on it that have burnished it well. As long as it is smooth it will finish better than if you lapped it and burnished it yourself.

Experiment with both sides, usually one side is more burnished than the other, if so then lap the non-burnished side to 600 Wet & Dry, so you have a hard ark progression. If it is scratched or badly dished, then you will have to lap it.

I doubt you will find a better finishing Ark for razors.

People have opinions about Blacks and Translucent, but most of that, is marketing hype. To get the most from a hard ark you must have a well finished 10-12 k edge, some 8k’s will work, or a smooth Washita, which is where the 600 step helps to finish, because the burnished will not cut and only polish.

I have several vintage Blacks and Translucent, and the grey, I believe they are capable of producing the same quality edge.

I say not to lap it because if it was well used, it has tons of time on it that have burnished it well. As long as it is smooth it will finish better than if you lapped it and burnished it yourself.

Experiment with both sides, usually one side is more burnished than the other, if so then lap the non-burnished side to 600 Wet & Dry, so you have a hard ark progression. If it is scratched or badly dished, then you will have to lap it.

I doubt you will find a better finishing Ark for razors.

I haven't done much with it but play with pocket knives and it appears to be pretty burnished because it's not cutting much of anything.It’s a combination black and translucent stone, I have a black with translucent streaks running through it. A few years ago, folks were calling them Translucent Grey stones. They can produce the same finish as a Surgical Black or Translucent.

People have opinions about Blacks and Translucent, but most of that, is marketing hype. To get the most from a hard ark you must have a well finished 10-12 k edge, some 8k’s will work, or a smooth Washita, which is where the 600 step helps to finish, because the burnished will not cut and only polish.

I have several vintage Blacks and Translucent, and the grey, I believe they are capable of producing the same quality edge.

I say not to lap it because if it was well used, it has tons of time on it that have burnished it well. As long as it is smooth it will finish better than if you lapped it and burnished it yourself.

Experiment with both sides, usually one side is more burnished than the other, if so then lap the non-burnished side to 600 Wet & Dry, so you have a hard ark progression. If it is scratched or badly dished, then you will have to lap it.

I doubt you will find a better finishing Ark for razors.

This came in the mail today, norton hard arkansas 5" x 1 ⁷/⁸"slip stone. Don't see black ones too often and I've never seen one that size. Anybody know the period for the label? The box and label look older than my other one. Finished a razor on it after a really old coticule > llyn idwal. I would've just finished with the LI normally because it gives amazing edges but I wanted to see if it would improve on that amazing edge. It did. My LI is more glassy than my Dan's blacks and feels more dense. It's extremely fine, maybe the finest finisher I've got and I've got a decent variety of finishers.i don't know if the ark made the edge finer but it was more aggressive. I have not shaved with it.