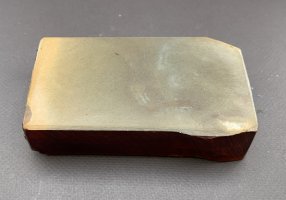

I have been honing on synthetics and pasted balsa for years with good success, at least in the end. Several weeks ago, I purchased a Jnat from a member here (thanks Steve!) and have been frolicking with it since. An interesting journey so far. Of course at first I could barely get an edge on a razor and certainly not a shaving edge but in the last week or two I finally stumbled on what I was doing wrong and have successfully put a shaving edge on several razors. Not the best edges known to man but sufficient for a reasonably close, comfortable shave even ATG. I have a couple of razors that Alfredo put a Jnat edge on quite a few years ago and while quite sharp and smooth, they do feel different than razors honed on extremely fine synthetic abrasives. First of all, I find that stropping is not beneficial on a razor that has been wiped on 0.5 micron Cr2O3 or 0.1 CBN pasted balsa. But it is not only beneficial on a razor honed on a Jnat, it is required to get a sharp, smooth edge. Further, additional stropping on a Jnat edge is beneficial while again, not much at all on a very fine synthetic edge.

It seems that there is a tooth or a set of grooves that grab hair out of proportion to the pressure used on a Jnat edge. In other words, the razor cuts much better than it should based on the feel of the blade against the skin. A synthetic edge can actually be sharper and yet takes a bit of pressure to actually cut hair. Both are smooth and comfortable to me, even shaving against the grain.

Certainly not jumping into the 'which one is better' ring here, just mentioning how I perceive at least some of the differences between the two edges. And of course this is based on a couple of Alfredo's edges from years ago, and my recent humble attempts with the only Jnat I have ever used. So no global, overall judgement but rather an early report on how they behave in my view.

Now if I can just avoid buying a pile of rocks just to see how they work, all will be well. So far, no problem ignoring that rabbit hole although I do have my eye on a different, more local stone that supposedly works well. So maybe just one more stone.....

It seems that there is a tooth or a set of grooves that grab hair out of proportion to the pressure used on a Jnat edge. In other words, the razor cuts much better than it should based on the feel of the blade against the skin. A synthetic edge can actually be sharper and yet takes a bit of pressure to actually cut hair. Both are smooth and comfortable to me, even shaving against the grain.

Certainly not jumping into the 'which one is better' ring here, just mentioning how I perceive at least some of the differences between the two edges. And of course this is based on a couple of Alfredo's edges from years ago, and my recent humble attempts with the only Jnat I have ever used. So no global, overall judgement but rather an early report on how they behave in my view.

Now if I can just avoid buying a pile of rocks just to see how they work, all will be well. So far, no problem ignoring that rabbit hole although I do have my eye on a different, more local stone that supposedly works well. So maybe just one more stone.....

. That is probably what you get for $3,000- a stone that jumps off the table and mutes your razors for you.

. That is probably what you get for $3,000- a stone that jumps off the table and mutes your razors for you.