Well, after the Larkin turned out so well I decided I'd have another go at this.

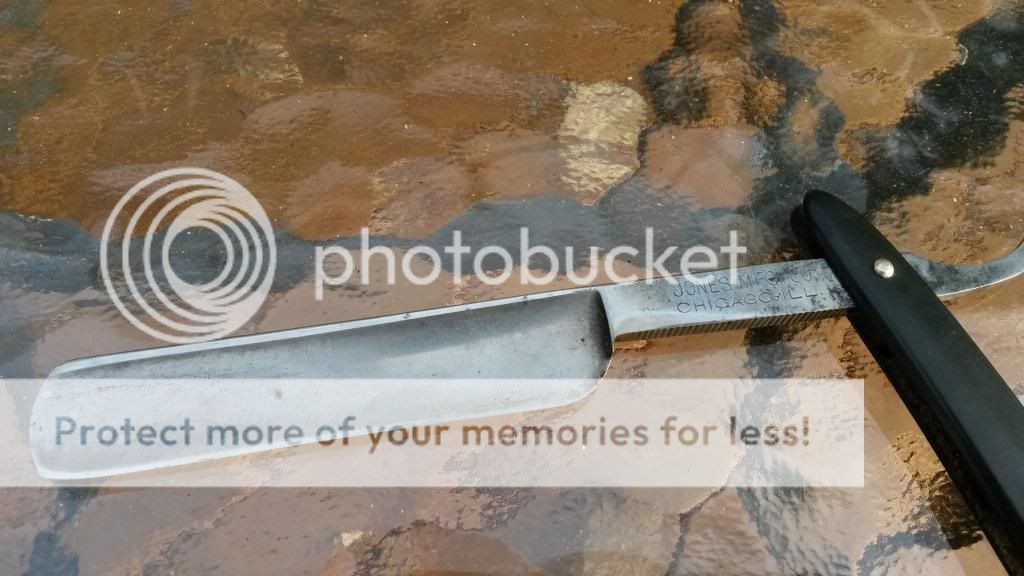

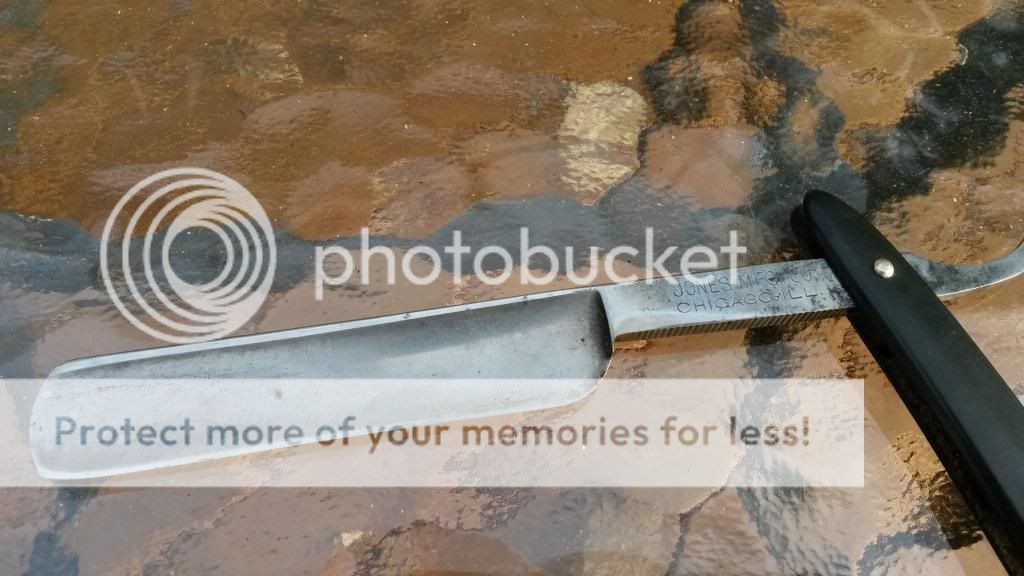

The Jones MFG Co came in this week, got if for less than $10 shipped. The blade has less rust and pitting than the Larkin but it has a slight frown I'll have to hone out.

Here's how I got it.

I unpinned it yesterday and here was the blade, so I got to work

after some time with 400 grit and WD40, I decided that I wasn't concerned getting all of the pitting removed...just cleaned up

and after some 600 that was previously used as a bevel setter(so not quite as course as true fresh 600 grit)

I had nothing else between the used up 600 grit and 1500...so I used the 1500 for a while

Next 2000

Then I went got some mother's polish and did a little more hand buffing with a tshirt scrap, not "brand new" mirror polish but good enough for a nice vintage shine

Then it was on to the scales. After using mahogany on the last one with a maple wedge I decided to use flamed maple on this one with a mahogany wedge.

I ripped a couple of just over 1/8" strips

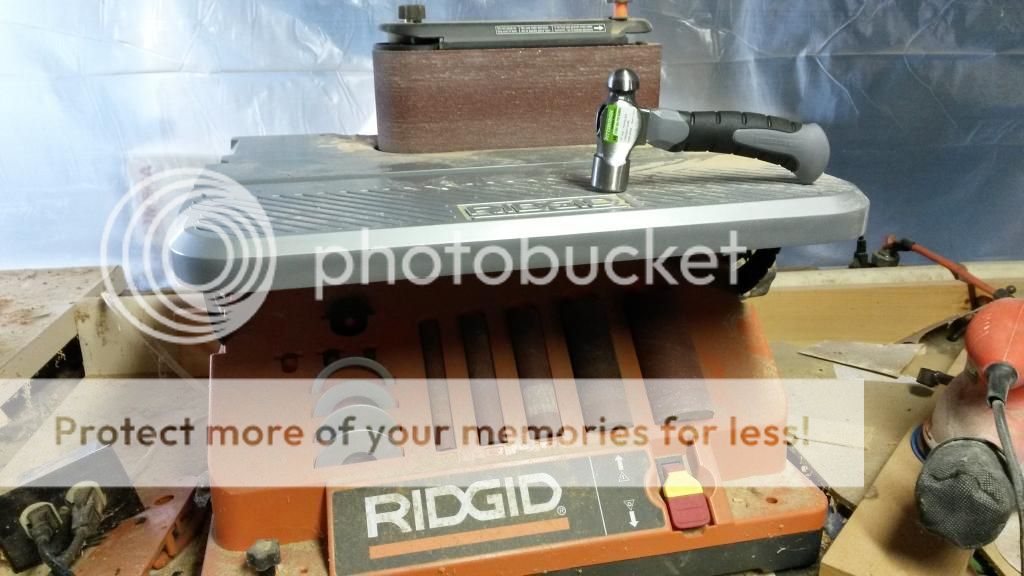

Cut it out and sanded to the line on the ROSS

Used the ROSS this time to contour since maple is so dang hard...the mahogany scales I shaped and contoured by hand, but the maple would have taken forever. After I roughed it out I then smoothed and finished it up with 150 and 220 grit

Now I have to decide if I just want tru-oil as the finish or hit it with some amber stain to bring out the flame in the maple...

The Jones MFG Co came in this week, got if for less than $10 shipped. The blade has less rust and pitting than the Larkin but it has a slight frown I'll have to hone out.

Here's how I got it.

I unpinned it yesterday and here was the blade, so I got to work

after some time with 400 grit and WD40, I decided that I wasn't concerned getting all of the pitting removed...just cleaned up

and after some 600 that was previously used as a bevel setter(so not quite as course as true fresh 600 grit)

I had nothing else between the used up 600 grit and 1500...so I used the 1500 for a while

Next 2000

Then I went got some mother's polish and did a little more hand buffing with a tshirt scrap, not "brand new" mirror polish but good enough for a nice vintage shine

Then it was on to the scales. After using mahogany on the last one with a maple wedge I decided to use flamed maple on this one with a mahogany wedge.

I ripped a couple of just over 1/8" strips

Cut it out and sanded to the line on the ROSS

Used the ROSS this time to contour since maple is so dang hard...the mahogany scales I shaped and contoured by hand, but the maple would have taken forever. After I roughed it out I then smoothed and finished it up with 150 and 220 grit

Now I have to decide if I just want tru-oil as the finish or hit it with some amber stain to bring out the flame in the maple...