- Thread starter

- #21

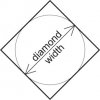

Thanks, Cal. This started with me, true, but its already a collaborative effort with your help. Thank you for your help. Oh, I thought of one more reason why "edge length" is more fitting. "Width" and "tab width" go together as the two obvious width measurements when you take width from (cutting) edge to edge. Similarly, "length" and "edge length" go together as the two obvious length measurements when you take length from tab to tab. Does that make sense? Has your mind been changed? Come on, Cal! I came around on "tab width"!

In the future, when I have enough data, I'll start the ShaveWiki page for blade dimensions that we've discussed here. The table will be sortable, so that you can reorder the rows by ascending or descending name, width, etc. There will be standard deviations, too, at least for blade width, so that we can see which blades vary more than others. Table data will be means (averages) and standard deviations with one row per blade. The blade names in the table will be links to the individual blade Wiki pages, where the individual blade sample measurements will be found, along with extra information, such as dates when the measurements were taken and when the samples were purchased. (I'm meticulous.) Quite a few blade pages already exist. I'll add to them and create new pages when necessary.

I'll post pictures of the polycarbonate fixtures after they are made. I'm still trying to settle on the best sheet thickness that's available, since I can't seem to find exactly what I want, but I'll get there. In the meantime, I am running a little experiment to determine if I can measure any difference in blade width between a new blade and a used blade. I'll post those results in due time. Even if I don't measure a difference, I will still prefer new blades for official measurements. If there is a difference, then width data for used blades will either have to be neglected or separated.

Even if I don't measure a difference, I will still prefer new blades for official measurements. If there is a difference, then width data for used blades will either have to be neglected or separated.

In the future, when I have enough data, I'll start the ShaveWiki page for blade dimensions that we've discussed here. The table will be sortable, so that you can reorder the rows by ascending or descending name, width, etc. There will be standard deviations, too, at least for blade width, so that we can see which blades vary more than others. Table data will be means (averages) and standard deviations with one row per blade. The blade names in the table will be links to the individual blade Wiki pages, where the individual blade sample measurements will be found, along with extra information, such as dates when the measurements were taken and when the samples were purchased. (I'm meticulous.) Quite a few blade pages already exist. I'll add to them and create new pages when necessary.

I'll post pictures of the polycarbonate fixtures after they are made. I'm still trying to settle on the best sheet thickness that's available, since I can't seem to find exactly what I want, but I'll get there. In the meantime, I am running a little experiment to determine if I can measure any difference in blade width between a new blade and a used blade. I'll post those results in due time.

Even if I don't measure a difference, I will still prefer new blades for official measurements. If there is a difference, then width data for used blades will either have to be neglected or separated.

Even if I don't measure a difference, I will still prefer new blades for official measurements. If there is a difference, then width data for used blades will either have to be neglected or separated.

Last edited:

).

).

Ah

Ah

I just responded to the thread by [MENTION=108562]dkeester[/MENTION] on center post width that you mentioned, Cal. I included some measurement data. Actually, I'll be updating my own thread on blade reveal parameters for the PAA DOC with caliper measurements. Keep you eyes peeled.

I just responded to the thread by [MENTION=108562]dkeester[/MENTION] on center post width that you mentioned, Cal. I included some measurement data. Actually, I'll be updating my own thread on blade reveal parameters for the PAA DOC with caliper measurements. Keep you eyes peeled.