No, it not one of the Orangies. It is a fairly even midtone grey, from memory. (I have it in storage at the moment. All my honing duties are split between a couple of coticules right now).

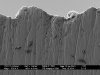

It is a very smooth surface, I can tell when it is getting close to maxing the edge, the razor really sticks to the surface when you flip it.

It is a very smooth surface, I can tell when it is getting close to maxing the edge, the razor really sticks to the surface when you flip it.