rbscebu

Girls call me Makaluod

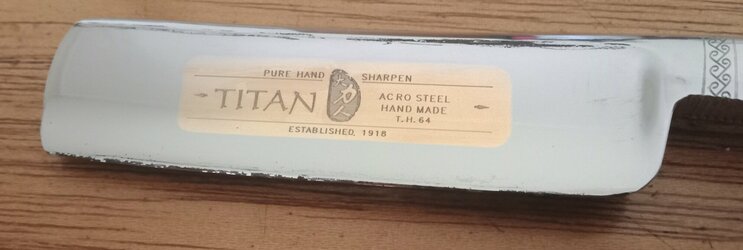

I received my new Titan 1918 ACRO T.H.64 with Ebony timber scales a few days ago. This SR is close to a ⅞ being 22mm wide, half-hollow, Dutch point and of a special martensitic stainless steel developed my Titan's steel manufacturer in Japan. The steel has been heat treated to a hardness of about 64 RHC with a fine grain structure and good inter-granular bonding. Cost was about USD 55 including shipping. This model SR it Titan's second top model (under their ACRO T.H-70) so it can be expected that they paid a little more attention to details. The ACRO T.H.64 was supplied with a mid-range Chinese strop (now with very thin leather, <1mm thick) and some "secret" stropping paste.

Starting today, I am going to work on this SR's edge to bring it up to my standard of shave-ready. I will report my progress in this thread as I go.

My gear consists of:

Next was a Sharpie pen test. I applied the Sharpie pen ink to both the bevel and spine-wear areas. The blade was then given 4 or 5 very light laps on the 8k whetstone.

The Sharpie results showed me that the bevel had been set with the spine raised above the honing medium and that the honing medium was not that flat.This arrangement would probably be acceptable to someone who is happy to maintain this SR on a pasted cloth strop. I am not one of those persons.

Next step will be to rest this SR's bevel to the way that I want it. I want my bevels to be perfectly flat and on the same plane as the spine wear. I will use the 1k whetstone to get close to a bevel set and finish the bevel set on the 3k whetstone. More about this in my next post in this thread.

Starting today, I am going to work on this SR's edge to bring it up to my standard of shave-ready. I will report my progress in this thread as I go.

My gear consists of:

Chinese synthetic whetstone of; 400, 1k, 3k, 8k and 10k grits. All have been freshly lapped flat.

Full set of lapping films with acrylic faced substrate; 30μm, 12μm, 9μm, 5μm, 3μm and 1μm.

Full set of diamond pasted balsa strops; 0.5μm, 0.25μm, 0.1μm and an additional 0.1μm for hanging.

I first examined the factory edge under strong sunlight. It was pretty good. There were two spots of the edge that reflected; one about 4mm long and another about 2mm long. Not bad for a factory edge.Next was a Sharpie pen test. I applied the Sharpie pen ink to both the bevel and spine-wear areas. The blade was then given 4 or 5 very light laps on the 8k whetstone.

The Sharpie results showed me that the bevel had been set with the spine raised above the honing medium and that the honing medium was not that flat.This arrangement would probably be acceptable to someone who is happy to maintain this SR on a pasted cloth strop. I am not one of those persons.

Next step will be to rest this SR's bevel to the way that I want it. I want my bevels to be perfectly flat and on the same plane as the spine wear. I will use the 1k whetstone to get close to a bevel set and finish the bevel set on the 3k whetstone. More about this in my next post in this thread.