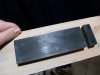

Got me a square of slate from lowes, and had the guy slice out 2 3 inch wide slabs of it. Total? 2 bucks (ok, 4 bucks since I got 2 squares, 4 slabs...) so, after 45 minutes with the DMT 325, I got a 12 inch long, absolutely flat plate of smooth stone. We'll see how she hones/shaves later (tonight?). Either way, a dollar well spent if it works, you know? Plus I have extra!

Don't be surprised/disappointed if your slate doesn't wind up being a super finishing stone. Though if it does... we may have to make a trade!