this will be just a little photo story of how i make my razor shaped objects....... i go start to finish with a couple videos..... this entire sequence was over 3 hours but actual working time was ~1~1:15mins....

anyone want a metal lollipop??

5mins later... front side done *(i don't remember the japanese word for it...)

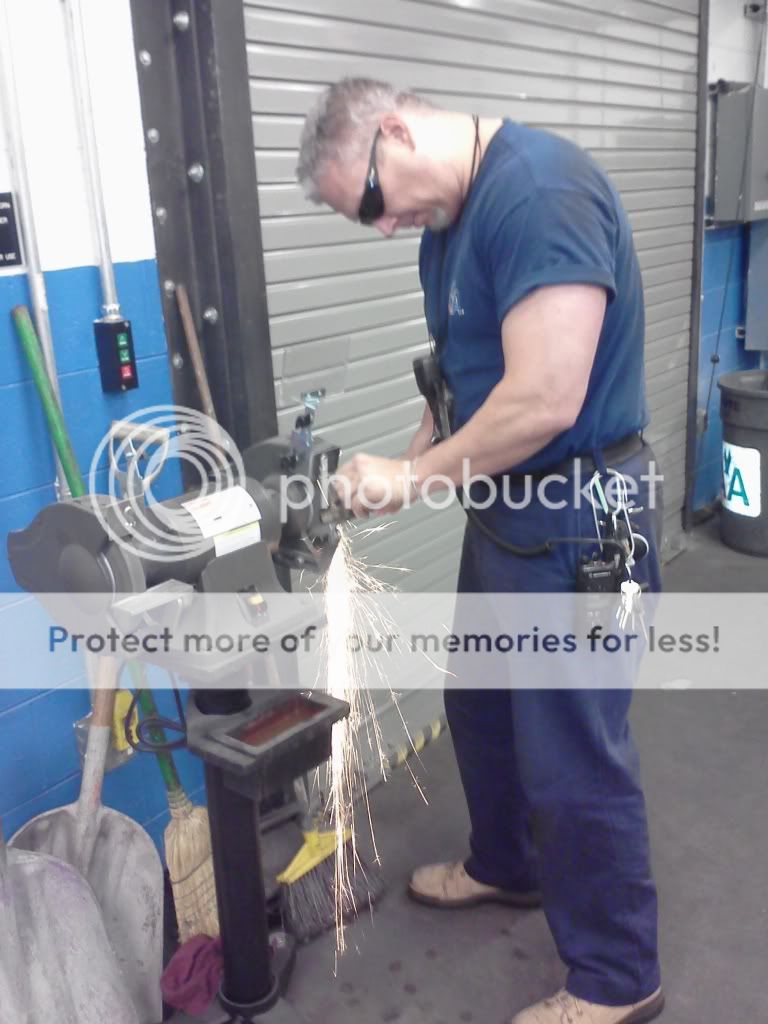

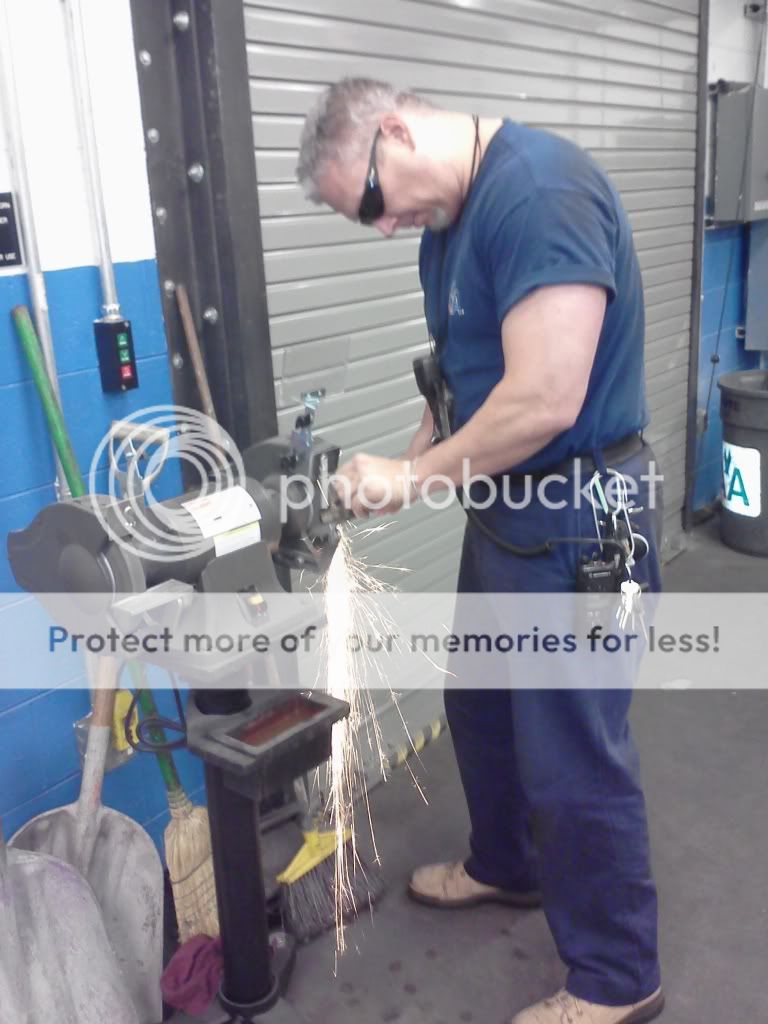

making sparks..

working on the other side.....

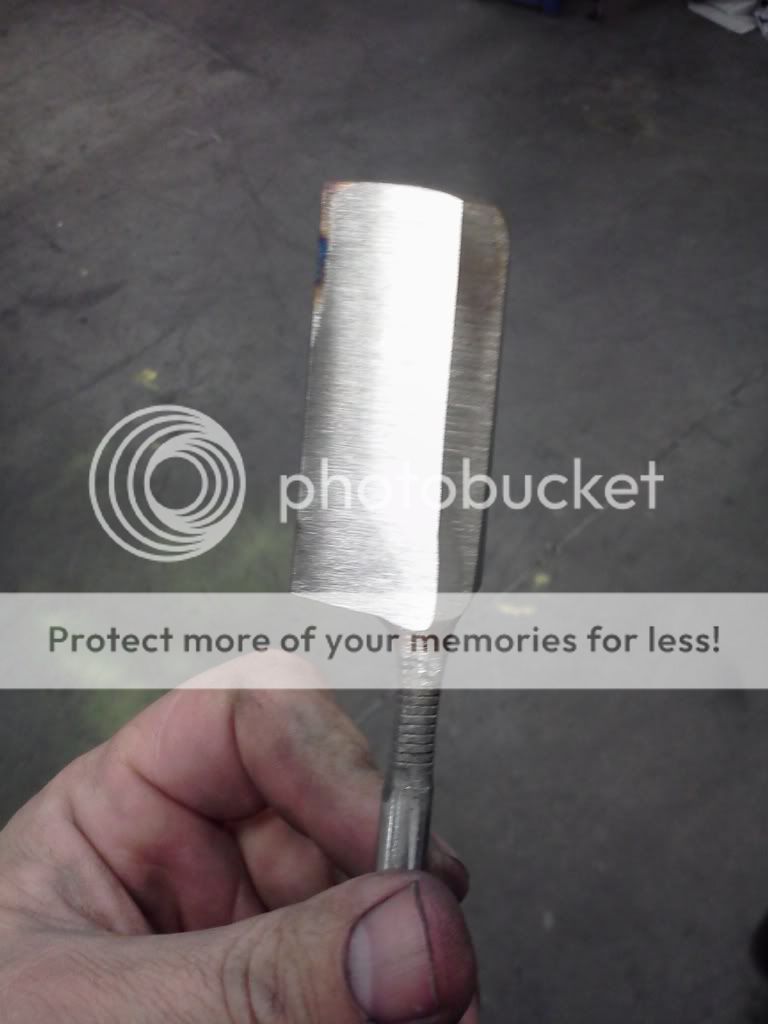

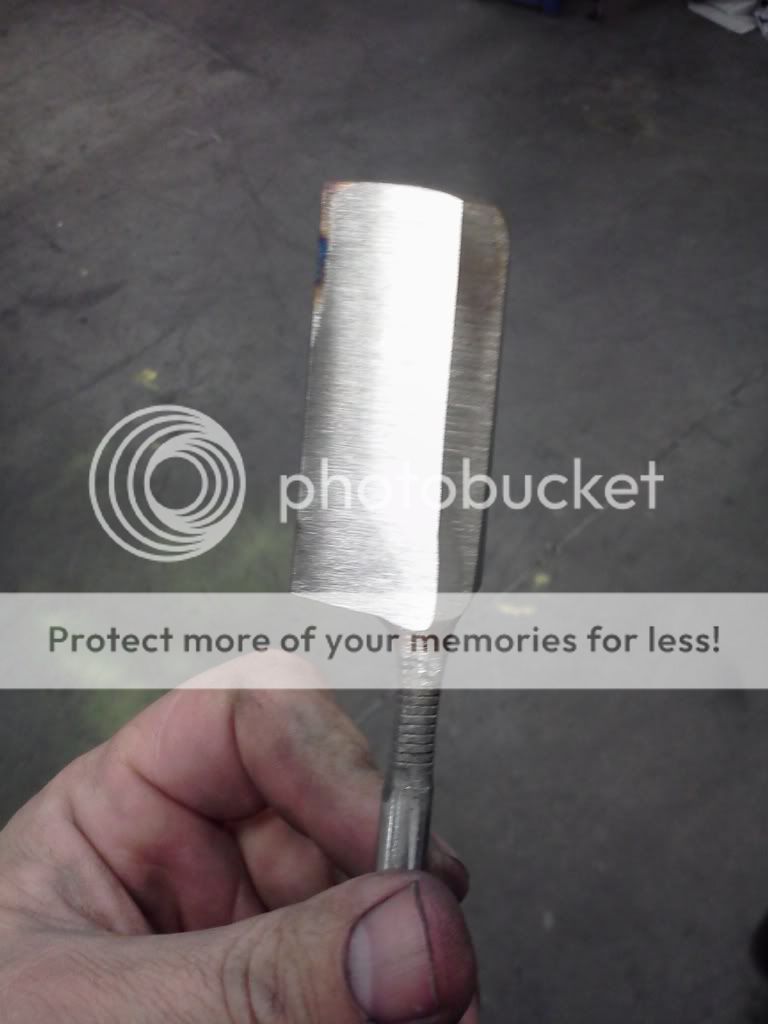

highly accurate inspection... lol..

hows it look to you??

heres a couple videos for you.....

anyone want a metal lollipop??

5mins later... front side done *(i don't remember the japanese word for it...)

making sparks..

working on the other side.....

highly accurate inspection... lol..

hows it look to you??

heres a couple videos for you.....

Last edited: